Expandable Polystyrene EPS Sandwich Roof Panels offer lightweight thermal insulation and cost-effective roofing. With an EPS core for energy efficiency and metal sheets for durability, they’re ideal for residential and commercial roofs. These panels ensure easy installation, weather resistance, and eco-friendly performance, delivering reliable, long-lasting protection.

Item No :

EPSROOF0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

18 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

Expandable Polystyrene Sandwich Roof Panels |

|

Thickness |

50/75/100/120/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

950/980mm |

|

Density |

8/10/12/14/16/18/20kg/m³ |

|

Skin material |

PPGL,PPGI,Stainless steel,aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

B2 |

|

Thermal Conductivity |

0.042 |

|

Temperature Range |

-40~90℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

The Expandable Polystyrene Sandwich Roof Panel is a game-changer for modern roofing, offering a perfect blend of energy efficiency, durability, and affordability. Designed with a low thermal conductivity of 0.038-0.043W/(m·K), this panel minimizes heat loss, ensuring stable indoor temperatures and reducing energy expenses for heating or cooling. It’s an excellent choice for those seeking thermal insulation roofing that delivers consistent performance.

This panel stands out for its cost-effectiveness, with economical raw materials, reduced shipping fees, and minimal installation expenses, making it a budget-friendly option for builders. At just 10kg/m², its lightweight design cuts down the building’s overall weight, lowering the costs of foundational and structural support while enhancing safety. This lightweight roofing solution is ideal for both small and large-scale projects.

Installation is seamless, thanks to its plug-in or splicing assembly, which speeds up construction and allows for easy on-site adjustments. This efficiency slashes project timelines, saving valuable time. Despite its light build, the panel offers impressive strength, featuring robust steel sheets paired with a resilient EPS core, providing reliable bending and compressive resistance to handle standard roof loads.

Aesthetically, these panels impress with vibrant, long-lasting colors and sleek designs, catering to various architectural styles. They resist fading for 10-15 years, and with periodic anti-corrosion coatings, their lifespan can exceed 35 years. Beyond looks, they provide effective soundproofing, dampening external noise to create peaceful interiors, perfect for offices or homes. As an eco-friendly choice, the EPS material is fully recyclable and emits no harmful substances, aligning with sustainable construction goals. Opt for the Expandable Polystyrene Sandwich Roof Panel to achieve durability, energy savings, and green building excellence.

Allowable vertical load and heat transfer coefficient of PROPANEL EPS sandwich roof panel (allowable deflection f ≤ L/240)

|

Thickness (mm) |

Heat transfer (W/㎡·k) |

Weight |

Load P=KN/m2 |

0.6 |

0.8 |

1 |

1.2 |

1.5 |

|

50 |

0.64 |

10 |

L(m) |

6.5 |

5.8 |

5.1 |

4.6 |

4 |

|

75 |

0.43 |

10.45 |

L(m) |

7.8 |

7 |

6.2 |

5.6 |

5 |

|

100 |

0.32 |

10.9 |

L(m) |

9.5 |

8.5 |

7.5 |

6.8 |

6 |

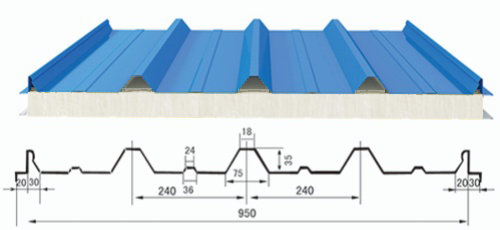

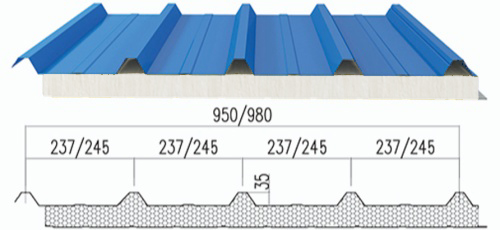

3 Joint Type for EPS Roofing Sandwich Panel

There are 2 kinds of lap type for EPS Roofing sandwich panel: one is cap type, another is overlap type.

Pictures are as below:

Cap Type 950 Roof Panel

Overlap Type 950 980 Roof Panel

4 Application of EPS Roofing Sandwich Panel

The Application of EPS Roofing Sandwich Panels transforms modern construction with their adaptability and performance across diverse sectors. These panels shine in mobile board rooms, offering a lightweight, easy-to-assemble solution for construction sites or event spaces, enabling swift setup and relocation. In large warehouses, their excellent thermal insulation ensures stable temperatures, perfect for storing sensitive goods like food or medicine, while reducing energy expenses. For clean workshops in industries such as electronics or pharmaceuticals, the panels provide a dust-free, hygienic surface that meets rigorous cleanliness standards, supporting precision manufacturing.

In medical facilities, EPS Roofing Sandwich Panels deliver consistent temperature regulation and soundproofing, creating serene, comfortable spaces for patient care and equipment storage. Their fire-retardant and moisture-resistant properties enhance safety and longevity, making them a reliable choice for both temporary setups and permanent structures like homes or farm buildings. Additionally, their durability ensures they withstand various environmental challenges, offering a long-term roofing solution.

These panels are also cost-effective and eco-friendly, crafted from recyclable materials to support sustainable building practices. Whether you’re an architect, contractor, or developer, the EPS Roofing Sandwich Panel offers unmatched versatility, boosting energy efficiency, safety, and comfort in applications ranging from industrial to residential projects. Choose this innovative material for a roofing solution that combines practicality with lasting value.

5 Project cases of EPS Sandwich Roof Panel

Project cases of EPS Sandwich Roof Panel--Kenya Farm 30,000 m2 2016

Project cases of EPS Sandwich Roof Panel--Saudi Machinery processing factory 5000 square meters 2019

6 FAQs for Propanel Expandable Polystyrene EPS Sandwich Roof Panel

Ⅰ What are the drawbacks of a sandwich panel roof?

Typical sandwich panel roofs may face load limitations and potential seam leaks in harsh weather, but Propanel's reinforced structure and advanced sealing technology overcome these issues effectively.

Ⅱ How long do EPS sandwich panels last?

EPS sandwich panels from Propanel are built to last 25-35 years with proper maintenance, thanks to their high-quality materials and durable construction that resists wear over time.

Ⅲ Why choose sandwich panels for construction?

Propanel sandwich panels provide exceptional thermal insulation, robust fire resistance, and effective noise reduction, making them a smart, efficient choice for modern construction projects of all kinds.

Ⅳ What’s the thickness of EPS sandwich panels?

Propanel EPS sandwich panels come in thicknesses ranging from 50mm to 200mm, offering flexibility to meet various insulation and structural needs across diverse building applications.

Ⅴ Are sandwich panels durable enough?

Yes, Propanel sandwich panels feature high-density cores that ensure outstanding durability, resilience, and long-term performance, making them ideal for demanding construction environments.

Ⅵ How strong are EPS sandwich panels?

Propanel EPS sandwich panels deliver a strong combination of excellent thermal insulation and reliable structural strength, enhanced by premium materials for lasting construction solutions.

Copyright @ 2025 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy