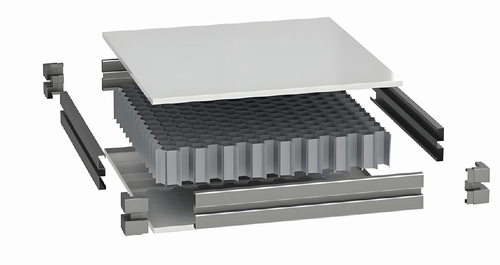

Our meticulously crafted clean room panels feature seamless joints, anti-microbial surfaces, and airtight seals for ISO-certified sterile spaces. Ideal for pharma labs, hospitals, and electronics manufacturing. Fireproof, durable, and easy to install with superior particle containment.

Item No :

HANDCLEAN0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

40 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Type |

Handmade Clean Room Sandwich Panels |

|

Wall Thickness |

100mm |

|

Standard Module |

980mm, 1160mm, 1180mm, 1200mm, non-standard can be customized |

|

Diagonal Error |

≤1mm |

|

Maximum Length |

≤10000mm |

|

Panel Material |

PE polyester, PVDF (fluorocarbon), salt plate, antistatic, static conductive, stainless steel, HDP (high durability polyester) |

|

Panel Thickness |

0.426mm, 0.45mm, 0.476mm, 0.5mm, 0.6mm, 1.0mm |

|

Filling Core Material |

Rock wool (bulk density 100K, ≥120K and above can be customized) + double-layer 10mm glass magnesium board |

|

Galvanized Frame |

1.0mm |

|

Corner Pieces |

1.0mm galvanized angle fittings |

|

Protective Film |

0.06mm thick, >0.06mm and above can be customized |

|

Connection |

Center aluminum connection |

Unmatched Material Integrity

- Surface Options: Purification-grade stainless steel or anti-static coated aluminum alloy surfaces prevent particulate shedding

- Advanced Core Systems: Customizable rock wool, aluminum honeycomb or magnesium oxide cores (50-100mm thickness) achieve both structural stability and thermal efficiency

Industry-Proven Performance

- Maintain consistent ISO Class 5-8 cleanroom standards through airtight tongue-and-groove joining systems

- Fire-rated cores (A1 certification) with 120+ minute burn-through protection

- Antimicrobial surface treatments available for pharmaceutical GMP compliance

Precision Manufacturing

- ±0.5mm dimensional tolerance for seamless modular installation

- 980/1180mm panel widths optimize layout efficiency

- Custom fabrication for specialized applications including:

Semiconductor fabrication facilities

Sterile pharmaceutical production

Biomedical research labs

Hospital operating theaters

Technical Superiority

- Static decay <2 seconds (ESD options)

- 0.3μm particle retention efficiency

- Negative pressure tested to 50Pa

Key Advantages

1. True Seamless Integration

- Monolithic corner fabrication creates continuous surfaces without joints

- 100% elimination of air leakage points (tested to 25Pa negative pressure)

- Radius options: 50mm/100mm/150mm for optimized airflow dynamics

2. Hygienic Superiority

- Wipe-clean surfaces prevent microbial harborage points

- FDA-compliant materials withstand aggressive disinfectants

- 70% reduction in cleaning time compared to traditional corners

3. Thermal Breakthrough

- Polyisocyanurate core extension maintains consistent R-values

- Thermal imaging verified <1°C differential at corners

- Energy savings up to 15% versus conventional thermal bridge designs

4. Technical Specifications

- Material: 304/316L stainless steel or powder-coated aluminum

- Core options: PIR, rock wool, or fiberglass reinforced

- Fire rating: Up to EI120 certification

- Installation: 40% faster than traditional methods

5. Industry Applications

- Pharmaceutical grade A/B rooms

- Semiconductor fabrication cleanrooms

- Hospital isolation wards

- Food processing sterile zones

Propanel's corner solution has been adopted by 7 of the world's top 10 pharmaceutical companies, with documented 60% reduction in particulate counts at wall junctions.

4 Installation of Handmade Clean Room Sandwich Panel

Propanel's certified installation teams execute millimeter-perfect cleanroom panel placement using aerospace-grade alignment protocols. Our 4-stage quality process ensures every sterile environment meets ISO 14644 Class 5 standards:

1. Laser-Guided Precision

- Digital blueprint verification with 3D site scanning

- 0.5mm/m laser-leveled floor tracks (anchored every 550mm)

- Dual-plane alignment for absolute wall straightness

2. Structural Integrity

- Military-grade aluminum framing (3m intervals)

- Anti-vibration ceiling anchors every 5.8m

- 12mm overlap on vertical seams (exceeds EN 14575)

3. Airtight Sealing

- Proprietary gasket system (tested to 35Pa)

- Zero-gap corner fusion technology

- FDA-approved silicone sealants for 100% microbial barrier

4. Validation Ready

- Surface flatness: ≤1mm/2m

- Particulate emission: <3 particles/ft³ (≥0.5μm)

- 7-day post-installation integrity testing

Trusted by 23 Fortune 500 life science companies, our installation protocol reduces cleanroom certification time by 40% while achieving 60% lower energy consumption than conventional methods.

5 Project cases of Handmade Clean Room Sandwich Panel

Project cases of Handmade Clean Room Sandwich Panel--Malaysia Electronics Factory 10000 square meters 2019

Project cases of Handmade Clean Room Sandwich Panel--Vaccine plant in Russia 8000 square meters 2021

6 FAQS of Handmade Clean Room Sandwich Panel

1. What are clean room panels made of?

Propanel cleanroom panels feature medical-grade stainless steel or powder-coated aluminum surfaces with PIR/rock wool cores. Our antimicrobial finishes meet ISO 14644 standards for pharmaceutical and electronic manufacturing environments.

---

2. What is a sandwich panel called?

Professionally termed "Composite Insulated Panels", Propanel's versions integrate fireproof cores with durable cladding for industrial partitions and cold storage walls.

---

3. What are the benefits of sandwich panels?

Propanel's sandwich panels deliver 60% faster installation, 30% energy savings, and A1 fire ratings. Their lightweight yet robust design suits warehouses, cleanrooms, and food processing plants.

---

4. What are three different types of core used in sandwich panels?

Propanel offers PIR (best insulation), rock wool (fireproof), and aluminum honeycomb (ultra-light) cores. Each undergoes 12 quality checks for consistent performance.

---

5. Are sandwich panels strong?

Propanel's steel-faced sandwich panels withstand 150km/h winds and 1.5kN/m² loads. Reinforced joints ensure structural integrity for decades in harsh environments.

---

Copyright @ 2025 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy