Item No :

HANDCLEAN0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

Magnesium glass plate: 0.8-1.2g/cm³ Rock wool: 40 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Type |

Handmade Glass Magnesium Rock Wool Purification Sandwich Panel |

|

Wall Thickness |

100mm |

|

Standard Module |

980mm, 1160mm, 1180mm, 1200mm, non-standard can be customized |

|

Diagonal Error |

≤1mm |

|

Maximum Length |

≤10000mm |

|

Panel Material |

PE polyester, PVDF (fluorocarbon), salt plate, antistatic, static conductive, stainless steel, HDP (high durability polyester) |

|

Panel Thickness |

0.426mm, 0.45mm, 0.476mm, 0.5mm, 0.6mm, 1.0mm |

|

Filling Core Material |

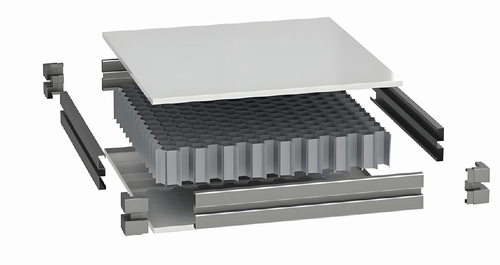

Rock wool (bulk density 100K, ≥120K and above can be customized) + double-layer 10mm glass magnesium board |

|

Galvanized Frame |

1.0mm |

|

Corner Pieces |

1.0mm galvanized angle fittings |

|

Protective Film |

0.06mm thick, >0.06mm and above can be customized |

|

Connection |

Center aluminum connection |

The Handmade Clean Room Sandwich Panel is a precision-crafted solution designed for cleanroom environments requiring exceptional purity and performance. Below are its key product features, tailored to meet the demands of high-stakes industries.

- Panel Materials: Made from purification-grade color-coated steel or aluminum alloy, these panels ensure a sterile, contamination-resistant surface. Ideal for sensitive settings like pharmaceutical labs and semiconductor production.

- Core Composition: Features high-performance cores such as rock wool, glass magnesium board, or aluminum honeycomb. This combination delivers superior thermal insulation, fire resistance, and structural integrity.

- Outstanding Performance: Produced through handmade or semi-automatic processes, each panel offers precise dimensions and undergoes a 100% inspection to guarantee flawless quality for cleanroom standards.

- Applications: Perfect for stringent indoor purification rooms in healthcare, electronics, and biotechnology. These panels serve as an ideal enclosure material, effectively blocking contaminants.

- Dimensions: Available in thicknesses of 50mm, 75mm, or 100mm and widths of 980mm or 1180mm, ensuring flexibility for diverse project needs.

- Surface Options: Choose between color-coated steel or stainless steel finishes. Customizable coatings include anti-static or antibacterial properties, with additional core variations like double gypsum rock wool, sulfur oxygen magnesium board, or foam board with glass magnesium grid.

Different from the traditional corner splicing combination, Propanel's one-piece corner board will make the board into a whole corner board, so that the corner location to achieve a smooth, seamless transition, the interface is tighter, to eliminate air leakage, seam dust accumulation phenomenon, easy to clean and disinfection. The special thermal insulation treatment of the one-piece corner board effectively avoids the common thermal bridge effect of traditional corners.

4 Installation of Handmade Clean Room Sandwich Panel

Accurate Layout and Alignment: Panels are crafted based on blueprints and on-site measurements. The floor track’s center line, set by intersecting ground points, ensures all lines align in one plane for perfectly straight walls.

Robust Installation Standards: Panels are installed per strict guidelines, with reinforced, sealed joints. Every 6000mm, they are secured to the ceiling with nails or screws, enhancing stability. Floor tracks, fixed every 600mm, accommodate pre-planned door positions and uneven surfaces, leveled for consistency, with large gaps sealed using sealant.

Precision Edge Finishing: Panels are custom-cut to fit, with edges refined for smoothness. Seamless joints and flatness are prioritized, supported by horizontal cross-keels every 3 meters. For vertical spans over 1.2 meters, overlapping joints of at least 10cm ensure strength.

Focus on Detail: Thorough preparation and attention to detail guarantee a flawless finish, maintaining cleanroom integrity. These features deliver a sterile, long-lasting solution for sensitive settings like labs or medical facilities.

5 Project cases of Handmade Clean Room Sandwich Panel

Project cases of Handmade Clean Room Sandwich Panel--Malaysia Electronics Factory 10000 square meters 2019

Project cases of Handmade Clean Room Sandwich Panel--Vaccine plant in Russia 8000 square meters 2021

Copyright @ 2025 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy