Item No :

HANDCLEAN0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

40 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

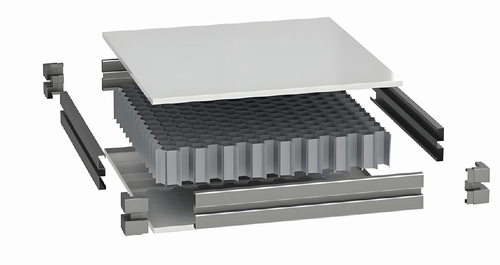

Type |

Handmade Hollow Glass Magnesium Purification Board |

|

Wall Thickness |

100mm |

|

Standard Module |

980mm, 1160mm, 1180mm, 1200mm, non-standard can be customized |

|

Diagonal Error |

≤1mm |

|

Maximum Length |

≤10000mm |

|

Panel Material |

PE polyester, PVDF (fluorocarbon), salt plate, antistatic, static conductive, stainless steel, HDP (high durability polyester) |

|

Panel Thickness |

0.426mm, 0.45mm, 0.476mm, 0.5mm, 0.6mm, 1.0mm |

|

Filling Core Material |

Rock wool (bulk density 100K, ≥120K and above can be customized) + double-layer 10mm glass magnesium board |

|

Galvanized Frame |

1.0mm |

|

Corner Pieces |

1.0mm galvanized angle fittings |

|

Protective Film |

0.06mm thick, >0.06mm and above can be customized |

|

Connection |

Center aluminum connection |

Clean board is a kind of building material used in places with high environmental cleanliness requirements, such as the medical field, electronics industry workshops, biotechnology pharmaceutical plants and laboratories, food and beverage industry and aerospace precision parts production assembly workshops.

Panel selection: Use purified grade color coated steel plate, aluminum alloy plate or stainless steel plate. Purified grade color coated steel plate has good corrosion resistance, decoration and cost performance; Aluminum alloy plate light weight, high strength and corrosion resistance; Stainless steel plate has higher corrosion resistance and hygiene performance, suitable for places with high cleanliness requirements.

Panel surface treatment: In order to meet the needs of different clean environments, the panel surface can be treated in a variety of ways. Common color processing, can provide a rich choice of color; There are also antistatic treatment, can effectively prevent dust adsorption, often used in the electronics industry and other electrostatic sensitive fields; And antibacterial treatment, can inhibit bacterial growth, suitable for medical, food and other industries.

Different from the traditional corner splicing combination, Propanel's one-piece corner board will make the board into a whole corner board, so that the corner location to achieve a smooth, seamless transition, the interface is tighter, to eliminate air leakage, seam dust accumulation phenomenon, easy to clean and disinfection. The special thermal insulation treatment of the one-piece corner board effectively avoids the common thermal bridge effect of traditional corners.

4 Installation of Handmade Clean Room Sandwich Panel

Accurate Layout and Alignment: Panels are crafted based on blueprints and on-site measurements. The floor track’s center line, set by intersecting ground points, ensures all lines align in one plane for perfectly straight walls.

Robust Installation Standards: Panels are installed per strict guidelines, with reinforced, sealed joints. Every 6000mm, they are secured to the ceiling with nails or screws, enhancing stability. Floor tracks, fixed every 600mm, accommodate pre-planned door positions and uneven surfaces, leveled for consistency, with large gaps sealed using sealant.

Precision Edge Finishing: Panels are custom-cut to fit, with edges refined for smoothness. Seamless joints and flatness are prioritized, supported by horizontal cross-keels every 3 meters. For vertical spans over 1.2 meters, overlapping joints of at least 10cm ensure strength.

Focus on Detail: Thorough preparation and attention to detail guarantee a flawless finish, maintaining cleanroom integrity. These features deliver a sterile, long-lasting solution for sensitive settings like labs or medical facilities.

5 Project cases of Handmade Clean Room Sandwich Panel

Project cases of Handmade Clean Room Sandwich Panel--Malaysia Electronics Factory 10000 square meters 2019

Project cases of Handmade Clean Room Sandwich Panel--Vaccine plant in Russia 8000 square meters 2021

5. FAQ of Handmade Purification Board

1.What's the main reason for using a sandwich panel in a structure?

--Sandwich panels are used in structures mainly for their excellent thermal insulation, high strength -to-weight ratio, good sound insulation, easy installation, and decorative properties. They offer multiple benefits that enhance the performance and appearance of the structure.

2.Are sandwich panels fire resistant?

--Different core materials sandwich panel fire rating is different, generally rock wool fire prevention is the best, is A level, followed by polyurethane. Customers can choose different core materials according to the requirements of the sandwich panel.

3.Do sandwich panels provide an internal and an external finish?

--Yes, Sandwich board has a variety of colors and styles to choose from, suitable for roof, wall, internal partition, ceiling and so on.

4.How long do sandwich panels last?

--The normal service life of the general sandwich board can reach more than 50 years.

5.What are the types of sandwich panels?

--According to the different core materials, it can be divided into EPS sandwich panel, PU sandwich panel, rock wool sandwich panel, glass wool sandwich panel. In addition, it can also be divided into cold storage sandwich panel and clean room sandwich panel according to the different use environment.

Copyright @ 2025 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy