Looking for high-performance purification boards? Our Mechanized Glass Magnesium Rock Wool Purification Board offers superior insulation and fire resistance. Made with durable glass magnesium and rock wool, it ensures excellent air quality. Ideal for various applications. Contact us today!

Item No :

HANDCLEAN0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

0.8-1.2g/cm³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

Mechanized Glass Magnesium Rock Wool Purification Board |

|

Core Material |

Rockwool,EPS,honeycomb,glass magnesium etc. |

|

Panel Thickness |

50/75/100/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

950/1150/980/1180mm |

|

Skin material |

PPGI, Pre-painted aluminum plate, SS Steel, Ti-Zn Steel etc. |

|

Pre-painted |

PE/HDP/PVDF |

|

Fireproof Grade |

A |

|

Length |

Customized. |

|

Customized design is welcomed. |

|

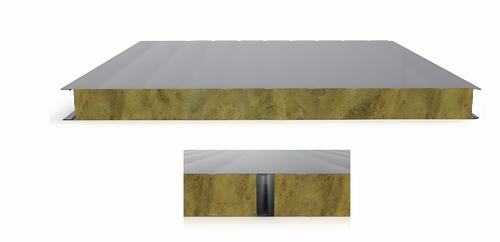

Propanel's mechanized purification boards redefine sterile environment construction through advanced manufacturing precision. Combining glass magnesium surfaces with high-density rock wool cores, these panels deliver unmatched performance for ISO Class 4-8 cleanrooms.

Industry-Specific Advantages

1. Pharmaceutical

- Autoclavable surfaces (withstands 121°C steam)

- CIP-compatible antibacterial coatings

2. Microelectronics

- Static dissipative options (106-109Ω surface resistance)

- Vibration-dampening aluminum honeycomb variants

3. Healthcare

- Seamless coved corners (R50/R100 radii)

- Fire-rated to EI 180 standards

Precision Manufacturing

- CNC-cut panels with ±0.3mm dimensional tolerance

- Automated sealant application (0.2mm bead consistency)

- 19-point quality verification including:

Negative pressure testing (50Pa)

Surface resistivity validation

Core density sampling

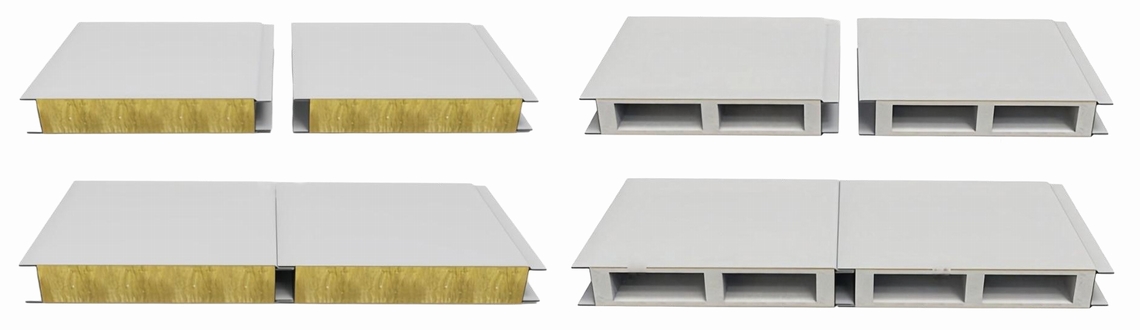

Propanel's revolutionary tongue-and-groove connection system redefines cleanroom panel installation with military-grade precision. Our patented interlocking technology ensures absolute seam integrity for critical environments:

Key Installation Advantages

- Zero-Tool Assembly: Unique pull-and-click mechanism enables 60% faster installation versus conventional systems

- Micro-Gap Elimination: Laser-calibrated joints achieve 0.1mm tolerance (validated by 25Pa negative pressure testing)

- Structural Reinforcement: Triple-lock design provides 2.5x greater shear strength than standard connections

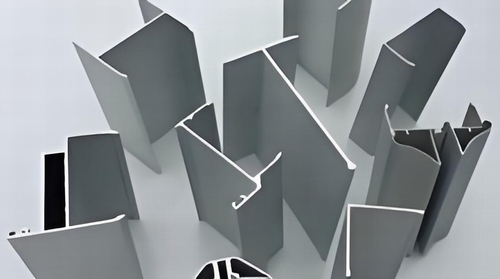

4 Clean Room Aluminum Profile Accessories

Propanel's clean room aluminum profile accessories are engineered to meet the exacting standards of ISO-certified sterile environments. Our aerospace-grade aluminum components deliver unmatched durability, cleanliness, and functionality for critical applications in pharmaceuticals, microelectronics, and biotechnology.

Key Product Features

- Material Excellence: 6063-T5 aluminum alloy with MIL-A-8625 anodization for corrosion resistance and ESD protection

- Modular Design: Tool-free assembly system reduces installation time by 45% versus traditional methods

- Particle Control: Smooth radius edges (R≥2mm) minimize particulate generation (<5 particles/ft³ at 0.5μm)

- Thermal Break: Polyamide insulation strips eliminate thermal bridging (ΔT<0.3°C)

Specialized Accessory Range

1. Structural Framing

- 50×50mm to 100×100mm profiles with T-slot channels

- Load capacity up to 350kg/m

2. Transition Components

- FDA-compliant silicone gaskets for airtight corners

- Antimicrobial door thresholds

3. Utility Integration

- Cable management raceways

- HEPA filter mounting brackets

5 Project cases of Mechanized Clean Room Sandwich Panel

Project cases of Mechanized Clean Room Sandwich Panel--Dubai Food Processing Factory 5000 square meters 2017

Project cases of Mechanized Clean Room Sandwich Panel--Singapore Laboratory 1000 square meters 2012

Copyright @ 2025 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy