Item No :

HANDCLEAN0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

0.8-1.2g/cm³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

Mechanized Hollow Glass Magnesium Purification Board |

|

Core Material |

Rockwool,EPS,honeycomb,glass magnesium etc. |

|

Panel Thickness |

50/75/100/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

950/1150/980/1180mm |

|

Skin material |

PPGI, Pre-painted aluminum plate, SS Steel, Ti-Zn Steel etc. |

|

Pre-painted |

PE/HDP/PVDF |

|

Fireproof Grade |

A |

|

Length |

Customized. |

|

Customized design is welcomed. |

|

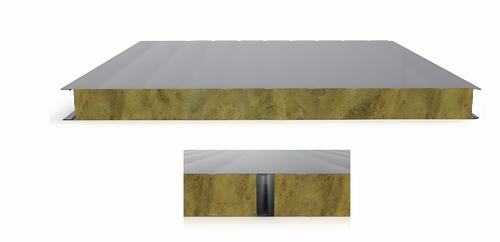

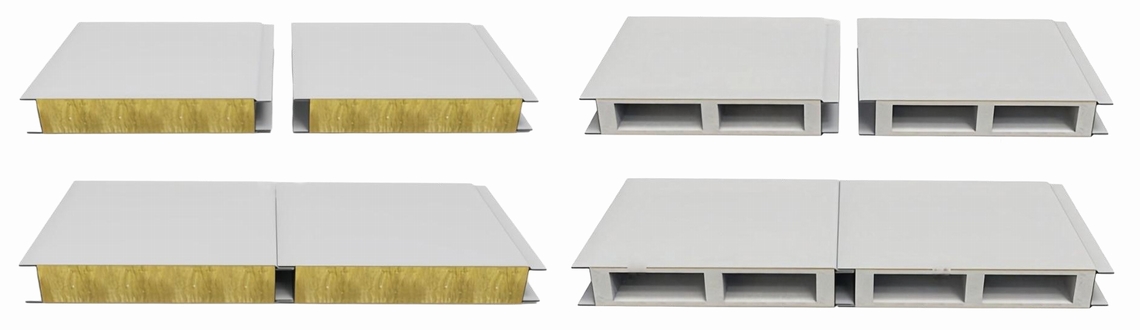

The Mechanized Clean Room Sandwich Panel is a precision-engineered solution designed for cleanroom environments, offering exceptional airtightness, structural strength, and customization. Below are its key product features, crafted for purity and efficiency.

Superior Airtightness: Ensures a contamination-free space for indoor ceilings, walls, and partitions, maintaining stable air quality in sensitive areas like pharmaceuticals and electronics.

High Load-Bearing Capacity: Combines core materials like rock wool, sulfur oxygen magnesium board, or honeycomb for robust durability and structural integrity, supporting large spans with precision bonding.

Flexible Installation: Supports both horizontal and vertical setups, adapting to diverse architectural needs with ease and application versatility.

Cleanroom-Optimized Design: Ideal for strict cleanliness standards in purification rooms, minimizing particle generation and simplifying maintenance.

Customizable Surface & Core Options: Choose from color steel or stainless steel with coatings like E, PVDF, HDP, or SMP for enhanced durability and functions such as antistatic or antibacterial properties. Core materials include rock wool, silicon rock, foam board, honeycomb, or glass magnesium grid board, tailored for insulation, acoustics, or fire resistance.

Adaptable Dimensions: Available in 50mm, 75mm, 100mm thicknesses and 950mm or 1150mm widths, fitting various spatial configurations seamlessly.

The Mechanized Clean Room Sandwich Panel utilizes a tongue-and-groove connection for easy, secure installation. Panels align precisely and interlock tightly through a pull-and-fit design, ensuring a strong, gap-free bond. This method delivers a flat, sturdy, and reliable surface, vital for maintaining cleanroom standards. Once installed, the panels remain stable and seamless, offering durability and practicality. Perfect for precision-driven environments, this connection ensures cleanliness and airtightness with minimal effort.

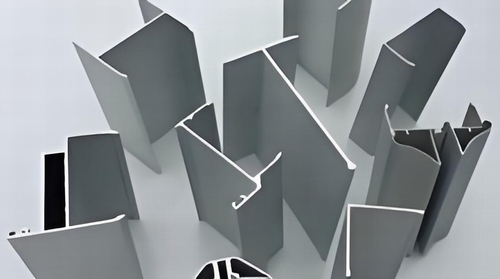

4 Clean Room Aluminum Profile Accessories

The Clean Room Aluminum Profile Accessories is designed for contamination-sensitive settings, delivering exceptional precision and durability. Crafted from high-quality aluminum, it offers corrosion resistance and easy maintenance, adhering to strict cleanroom standards. Its modular structure ensures fast assembly and seamless compatibility, minimizing installation time and contamination risks. Lightweight yet strong, it supports heavy loads while maintaining structural integrity. Perfect for pharmaceutical, biotech, and electronics industries, this panel guarantees long-lasting reliability and superior cleanliness. Opt for this solution for an efficient, contamination-free cleanroom environment.

5 Project cases of Mechanized Clean Room Sandwich Panel

Project cases of Mechanized Clean Room Sandwich Panel--Dubai Food Processing Factory 5000 square meters 2017

Project cases of Mechanized Clean Room Sandwich Panel--Singapore Laboratory 1000 square meters 2012

Copyright @ 2025 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy