Best choice for cold chain applications. With a thermal conductivity of 0.023W/(m·K), excellent thermal insulation properties. Made of high-strength steel , they offer easy installation and strong impact resistance. Fire-proof and moisture-proof, they come in various specs for customization.

Item No :

ColdStorage0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

40 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

Pir Cold Room Sandwich Panel |

|

Density |

40~45kg/m³ |

|

Thickness |

40/50/60/75/80/100/120/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

1000mm for wall and roof |

|

Skin material |

PPGL,PPGI,Stainless steel,aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

B1 |

|

Thermal Conductivity |

≤0.023/≤0.02 |

|

Temperature Range |

40~43/40~50℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

Compared with other cold storage panel materials (such as polystyrene, rock wool, etc.), PU cold storage panels have significant and unique advantages in different application scenarios:

Food cold chain field

Outstanding thermal insulation and cold preservation: In the links of food production, storage, and transportation, extremely high requirements are imposed on temperature control. The thermal conductivity coefficient of PU cold storage panels is as low as 0.023W/(m・K), which can effectively reduce heat transfer, stabilize the temperature inside the cold storage, and reduce the risk of food deterioration. Taking the fruit fresh-keeping warehouse as an example, a stable low-temperature environment can prolong the fresh-keeping period of fruits and reduce losses. In contrast, the thermal conductivity coefficient of polystyrene cold storage panels is relatively high, and the thermal insulation effect is poor, making it difficult to maintain a stable low temperature for a long time.

Hygienic, safe, and reliable: The food industry has strict hygiene requirements. The surface of PU cold storage panels is smooth, not prone to the growth of bacteria and molds, and its chemical properties are stable and will not react with food, ensuring food safety. For example, in dairy cold storage, PU cold storage panels can avoid contaminating dairy products, while the fibers of rock wool panels are easily detached and may contaminate food, presenting a hygiene hazard.

Pharmaceutical industry

Precise temperature control: The storage of drugs and vaccines requires an accurate temperature range. The good thermal insulation performance of PU cold storage panels helps achieve precise temperature control and ensures the effectiveness and stability of drugs and vaccines. For instance, when storing temperature-sensitive biological products, PU cold storage panels can control temperature fluctuations within a very small range, while other materials may cause large temperature fluctuations due to poor thermal insulation, affecting drug quality.

Superior fire resistance: Pharmaceutical warehouses store a large amount of drugs and medical supplies, and fire prevention is of utmost importance. PU cold storage panels have better fire resistance performance and can to a certain extent prevent the spread of fire and reduce fire losses. In comparison, polystyrene cold storage panels are flammable and have a higher fire risk.

Chemical field

Resistant to chemical corrosion: Chemical raw materials and products are corrosive. PU cold storage panels have good chemical stability and can resist the erosion of various chemical substances, making them suitable for the storage of chemical products. For example, when storing some acidic or alkaline chemical raw materials, PU cold storage panels will not be corroded and damaged, while other materials may have a reduced service life due to corrosion.

High strength and impact resistance: In chemical warehouses, goods are frequently handled, and cold storage panels need to have a certain strength. PU cold storage panels use high-strength materials and unique splicing designs, have strong impact resistance, can withstand the impact of goods collisions and handling equipment, and ensure the stability of the cold storage structure.

Electronic industry

Excellent moisture-proof performance: Electronic components are sensitive to humidity, and a humid environment will affect their performance and lifespan. PU cold storage panels have excellent moisture-proof performance and can effectively prevent moisture from entering the cold storage and protect electronic components from being damaged by moisture. In electronic chip storage warehouses, PU cold storage panels can maintain a low humidity environment inside the warehouse and ensure chip quality.

Environmentally friendly and energy-saving: The electronic industry pays attention to environmental protection and energy conservation. PU cold storage panels have good thermal insulation performance, which can reduce the energy consumption of refrigeration equipment, reduce energy consumption and carbon emissions, and meet the green development requirements of the electronic industry.

3 The Technical Specifications of Cold Storage Sandwich Panel

|

Thickness /mm |

Temperature difference between inside and outside/℃ |

Height of wall panel/m |

Length of roof panel/m |

Applicable cold storage temperature/℃ |

|

100 |

30 |

5 |

4.45 |

-15 |

|

125 |

35 |

5.5 |

5.2 |

-20 |

|

150 |

50 |

6 |

5.85 |

-25 |

|

175 |

65 |

6.5 |

6.3 |

-30 |

|

200 |

75 |

7 |

6.8 |

-40 |

The data shown in the left table are only available for the panel which subject to the internal-external pressure difference and contraction pressure, without wind load. If the specified length/height is exceeded or wind load occurs, panel supporters are required.

The above data are calculated according to the heat flow of 8~10W/m2.

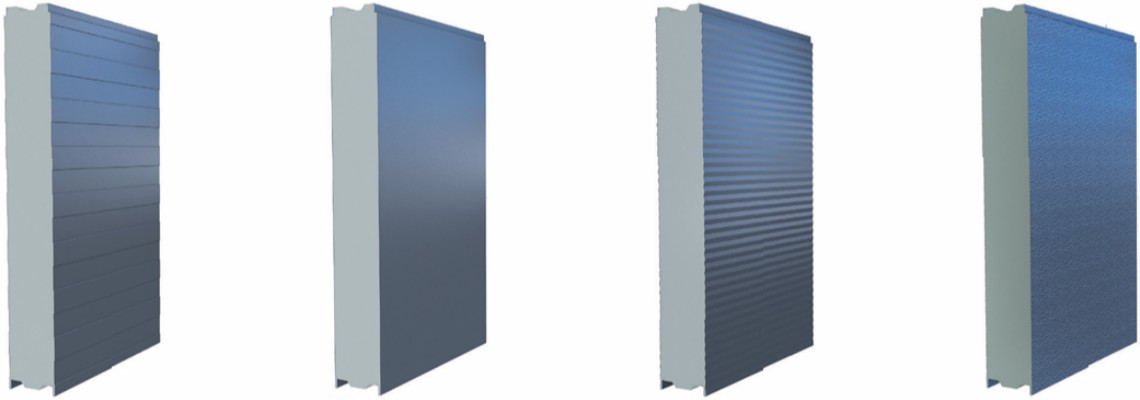

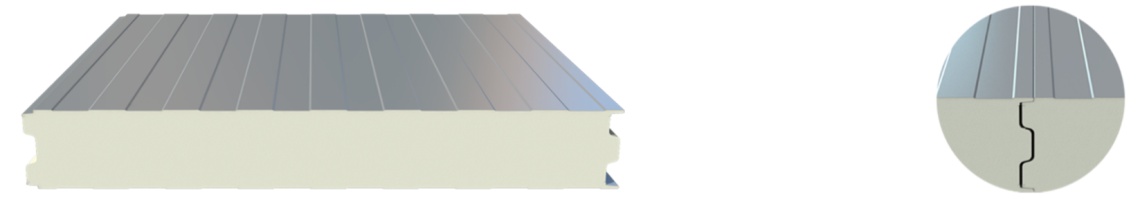

4 Plate Type and Node Figure

Cold storage board plug-in interface-C type

Cold storage board plug-in interface-E type

5 Application Areas of Cold Storage Panels

·Fast frozen processing and refrigeration of food

·Food processing plant

·Storage of dairy products

·Biological products and medicines

·Indoor cold storge

·Cold storages for cold-chain transportation vehicle

6 FAQ of PIR Cold Room Sandwich Panel

1. What is the temperature of a PU sandwich panel?

--Different temperatures require different thickness of the panels.

|

Thickness of PU panel |

Application temperature |

|

75mm |

-5℃ or above |

|

100mm |

-15℃ or above |

|

120mm |

-25℃ or above |

|

150mm |

-35℃ or above |

2. At what temperature does PU melt?

--The melting temperature of PU (polyurethane) is generally about 180℃ -250 ℃.

However, the specific melting temperature will vary depending on the specific type of PU, formula and additives. For example, some specially modified PU may have a higher or lower melting temperature.

3. Is PU fire-proof?

--PU foam is not inherently fire-resistant by itself. Its chemical composition includes organic compounds that are prone to combustion. However, the fire resistance of PU can be enhanced through adding flame retardant.

4. What is the R value for PU sandwich panel?

The R value is an indicator of the thermal insulation performance of a material, expressed in square feet, degrees Fahrenheit, hours/British thermal units (ft ², ° F, h/Btu). The following is a reference table for the approximate R value of polyurethane (PU) foam boards of different thicknesses:

|

PU Thickness(Inch) |

R Value(approximate value) |

|

1 |

5.0 - 6.0 |

|

2 |

10.0 - 12.0 |

|

3 |

15.0 - 18.0 |

|

4 |

20.0 - 24.0 |

|

6 |

30.0 - 36.0 |

It is important to note that the actual R value may be affected by a variety of factors such as material density, formulation, production process, and use environment, and the specific value may vary.

5. What is a polyurethane sandwich panel used for?

Our polyurethane sandwich panels are widely applied. In construction, they are used for building walls, roofs, and partitions in residential, commercial, and industrial buildings, offering excellent thermal insulation and energy - saving benefits. In cold storage and refrigerated transportation, they maintain low temperatures. In agriculture, they're used in greenhouses and animal sheds for temperature control. Additionally, they are applied in industrial equipment insulation, like for pipes and tanks, and can be used for office interior partitions due to their sound - proofing and easy - installation features.

Copyright @ 2025 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy