Lightweight Polyurethane Polyurethane PU PIR Wall Sandwich Panel for superior thermal insulation, fire resistance, and weatherproofing. Ideal for industrial, commercial, and cold storage projects. Easy installation, eco-friendly, energy-efficient, and cost-saving.

Item No :

PUWall0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

40 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

Polyurethane PU PIR Wall Sandwich Panel |

|

Density |

40~45kg/m³ |

|

Thickness |

40/50/60/75/80/100/120/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

1000mm for wall and roof |

|

Skin material |

PPGL,PPGI,Stainless steel,aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

B1 |

|

Thermal Conductivity |

≤0.023/≤0.02 |

|

Temperature Range |

40~43/40~50℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

PU Sandwich Wall Panels stand out as a premier building solution, blending high-performance features with innovative design. These panels achieve an exceptional thermal conductivity of ≤0.02 W/(m·K) at 20°C, ensuring top-tier insulation and energy efficiency. Their lightweight yet self-supporting structure makes them ideal for interior partitions, ceilings, and even mobile container house walls, eliminating the need for additional framing. The panels excel in fire safety, boasting non-combustible properties that prevent flame spread, smoke generation, or dripping during a fire, enhancing occupant safety.

Designed for architectural versatility, PU Sandwich Wall Panels offer decorative facades with a variety of metal finishes—color-coated steel, aluminum foil, galvanized steel, or stainless steel—developed in collaboration with paint factories. Using cutting-edge technology, natural colors and textured effects are replicated on the surface, enhancing aesthetic appeal. Pre-fabricated in factories, these panels and their structural components slash on-site installation time by up to 50% compared to traditional walls, streamlining construction projects.

Beyond insulation, they provide excellent air-tightness and cold bridge prevention, maintaining consistent indoor temperatures. This combination of durability, fire resistance, and eco-friendly design makes PU Sandwich Wall Panels a top choice for modern, sustainable construction, meeting both functional and aesthetic demands efficiently.

Allowable vertical load and heat transfer coefficient of PROPANEL polyurethane sandwich wall panel (allowable deflection f ≤ L/200)

|

Thickness (mm) |

Heat transfer (W/m2k) |

Weight (kg) |

Load P=KN/m2 |

0.60 |

0.80 |

1.00 |

1.20 |

1.50 |

|

50 |

0.31 |

10.06 |

L(m) |

3.52 |

3.04 |

2.69 |

2.42 |

2.11 |

|

75 |

0.21 |

11.06 |

L(m) |

4.71 |

4.09 |

3.64 |

3.29 |

2.89 |

|

100 |

0.19 |

12.05 |

L(m) |

5.76 |

5.02 |

4.47 |

4.05 |

3.56 |

|

120 |

0.16 |

12.84 |

L(m) |

6.53 |

5.68 |

5.07 |

4.60 |

4.04 |

|

150 |

0.11 |

14.04 |

L(m) |

7.56 |

6.58 |

5.87 |

5.32 |

4.68 |

Note:0.5mm outer steel sheet and 0.4mm inner steel sheet.

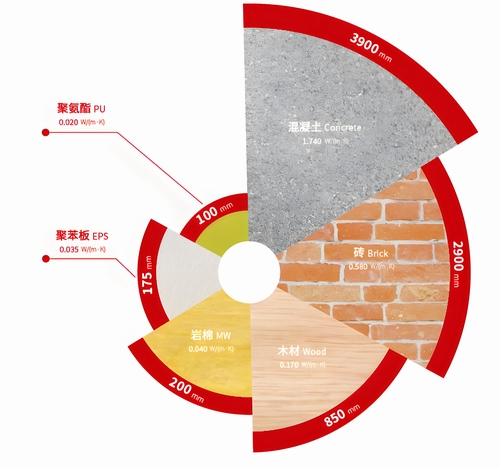

3 Advantages of PU Polyurethane and Rock wool core material

Comparison of different core thicknesses under the same insulation effect

-Thermal insulation performance

Polyurethane composite panels with good thermal insulation effect, general ideal state, 50mm polyurethane composite panels with thermal insulation effect equivalent to 1720mm brick wall.

Rock wool composite board insulation effect is good, rock wool fiber thin and flexible, low thermal conductivity, with excellent thermal insulation effect.

-Fire performance

Polyurethane composite panels with good fire performance, with the characteristics of self-extinguishing from the fire, fire level up to B1.

Rock wool composite board uses water-repellent rock wool tape as the main core material for heat preservation, which reaches Class A fireproof standard.

-Energy saving and environmental protection

Composite panels are energy-saving and environmentally friendly, as they are easy to install and can be recycled, greatly improving the reuse rate of the panels.

4 Sandwich Panel Technical points--Waterporoof

The ongoing three hour spray test PU Polyurethane Sandwich Wall Panel

PU Sandwich Wall Panels with Triple-Layer Waterproof Design – Ultimate Protection & Thermal Efficiency

PU Sandwich Wall Panels integrate a revolutionary triple-layer waterproof system, ensuring unmatched durability and weather resistance for industrial, commercial, and cold storage applications.

1st Layer: Interlocking Fish-Scale EPDM Gasket Seal

The embedded EPDM rubber strip features a precision-engineered "fish-scale" design, with a width exceeding joint gaps for a compression-fit seal. Multiple drainage channels create negative-pressure cavities, enhancing adhesion and preventing gasket displacement even under extreme conditions.

2nd Layer: High-Performance Weather-Resistant Sealant

Industrial-grade sealant is applied at joint bases to reinforce waterproofing integrity. This UV-stable, flexible compound resists cracking and aging, maintaining long-term watertight performance in harsh climates.

3rd Layer: Serrated-Edge EPDM Rubber Pad (Thermal Bridge Prevention)

The zigzag-shaped EPDM pad forms directional drainage grooves to actively divert moisture outward while blocking thermal bridges at panel joints. This dual-action design eliminates condensation risks and enhances energy efficiency.

5 Why Choose Our Panels?

Ideal for warehouses, food processing plants, pharmaceutical storage, and coastal buildings. Reduce maintenance costs by 40% while achieving superior insulation (R-values up to 6.5 per inch). Upgrade to leak-proof, energy-saving PU/PIR core panels – the smart choice for climate-critical construction.

Copyright @ 2025 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy