Excellent insulation performance, lightweight texture, easy installation, and excellent decorative, can mimic a variety of textures and shapes. And has good water resistance and corrosion resistance, can be maintained for a long time.

Item No :

PUWall0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

40 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

PU Polyurethane Sandwich Wall Panel |

|

Density |

40~45kg/m³ |

|

Thickness |

40/50/60/75/80/100/120/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

1000mm for wall and roof |

|

Skin material |

PPGL,PPGI,Stainless steel,aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

B1 |

|

Thermal Conductivity |

≤0.023/≤0.02 |

|

Temperature Range |

40~43/40~50℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

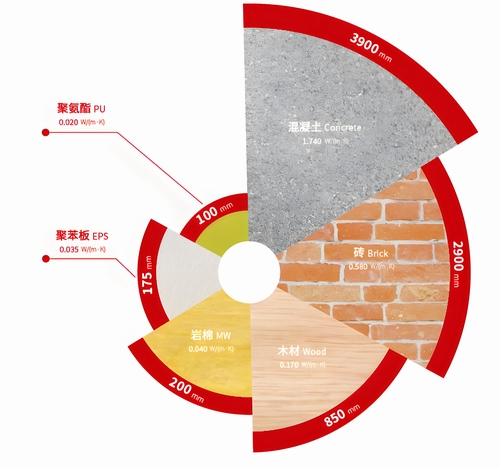

Polyurethane thermal conductivity is very low, when its density is 35 ~ 40kg/m3, the thermal conductivity is only 0.018~0.024W/ (m·k), which is the lowest thermal conductivity of all thermal insulation materials, which has excellent thermal insulation performance. Under the same thermal insulation requirements, the thickness of the outer protective structure of the building is reduced, thereby increasing the indoor use area.

The porosity structure of polyurethane materials is stable, basically a closed cell structure, the closed cell ratio is more than 90%, and it is a hydrophobic material, which will not increase the thermal conductivity due to moisture absorption, and the wall will not seep water. Not only good insulation performance, but also freeze-thaw resistance, sound absorption is good. The average life of rigid foam polyurethane insulation structure can reach more than 30 years under the conditions of normal use and maintenance. It can be achieved under normal service conditions during the life of the structure, it will not be damaged under dry, wet or electrochemical corrosion, as well as due to external influences such as insect, fungal or algal growth or due to damage by rodents.

Polyurethane is a flame-resistant self-extinguishing material with a softening point of more than 250 degrees Celsius and decomposition occurs only at higher temperatures: In addition, polyurethane will form carbon deposits on the surface of its foam when it burns, which helps isolate the underlying foam. It can effectively prevent the spread of flame. Moreover, polyurethane does not produce harmful gases at high temperatures.

Allowable vertical load and heat transfer coefficient of PROPANEL polyurethane sandwich wall panel (allowable deflection f ≤ L/200)

|

Thickness (mm) |

Heat transfer (W/m2k) |

Weight (kg) |

Load P=KN/m2 |

0.60 |

0.80 |

1.00 |

1.20 |

1.50 |

|

50 |

0.31 |

10.06 |

L(m) |

3.52 |

3.04 |

2.69 |

2.42 |

2.11 |

|

75 |

0.21 |

11.06 |

L(m) |

4.71 |

4.09 |

3.64 |

3.29 |

2.89 |

|

100 |

0.19 |

12.05 |

L(m) |

5.76 |

5.02 |

4.47 |

4.05 |

3.56 |

|

120 |

0.16 |

12.84 |

L(m) |

6.53 |

5.68 |

5.07 |

4.60 |

4.04 |

|

150 |

0.11 |

14.04 |

L(m) |

7.56 |

6.58 |

5.87 |

5.32 |

4.68 |

Note:0.5mm outer steel sheet and 0.4mm inner steel sheet.

3 Advantages of PU Polyurethane and EPS core material

-Insulation performance: Both PU and EPS have good insulation properties, but PU has a lower thermal conductivity, offering better insulation.

-Strength-to-weight ratio: PU has a higher strength-to-weight ratio, being lightweight yet strong, while EPS is very lightweight with relatively lower strength.

-Waterproofing: PU has excellent waterproofing properties due to its dense closed-cell structure, while EPS has relatively low water absorption but is not as waterproof as PU.

-Cost: EPS is generally less expensive than PU, making it a more cost-effective option for some projects.

-Fire resistance: PU can be made fire-retardant to a certain extent, while EPS is combustible and has poor fire - resistance if not treated with fire-retardant agents. However, even when treated, its fire -resistance is usually not as good as that of PU.

4 Sandwich Panel Technical points--Waterporoof

The ongoing three hour spray test PU Polyurethane Sandwich Wall Panel

The Propanel Difference

- Micro-Tolerance Manufacturing: Laser-guided production ensures ±0.3mm seam accuracy - 5x tighter than industry norms

- Material Science: Proprietary EPDM blends maintain elasticity from -60°C to 120°C (tested per ASTM D412)

- Validation Protocol: Every 1000th panel undergoes 72-hour cyclone simulation (200km/h winds + horizontal rain)

Waterproofing Breakthroughs

1. Dual-Phase Gasket System

- Diamond-patterned EPDM with 3D drainage channels

- 300% greater compression recovery vs standard gaskets

2. Nano-Fortified Sealants

- Graphene-enhanced polymers resist UV degradation for 25+ years

- Self-healing properties seal minor abrasions automatically

3. Thermal Break Technology

- Aerogel-insulated joint blockers reduce energy loss by 18%

- ICC-ES approved for coastal flood zones

Quality That Performs

- 0% water penetration at 3000Pa pressure (EN 1027 tested)

- 40-year warranty on waterproof integrity

- 37% faster installation with our patented SnapSeam™ system

5 Why Choose Our PU Wall Sandwich Panels?

1. Unmatched Thermal Efficiency

- Ultra-Low Conductivity: 0.022 W/m·K core ensures 40% better insulation than EPS panels

- Airtest™ Sealing: Patented joints reduce thermal bridging by 90%, maintaining consistent temperatures

2. Industrial-Grade Durability

- Cyclone-Proof: Withstands 150mph winds (ASTM E330 tested)

- Corrosion Resistance: Marine-grade aluminum cladding survives saltwater exposure for 30+ years

3. Smart Installation

- ClickLock™ System: 50% faster assembly than traditional panels

- Precision Tolerances: ±1mm dimensional accuracy for seamless finishes

4. Certified Safety

- Fire Performance: EN 13501-1 Class B-s1,d0 rating

- Hygienic Surfaces: NSF-approved coatings for food/pharma applications

5. Cost Leadership

- 60% lower lifetime costs vs concrete walls

- 15-year warranty on thermal performance

6 FAQs of PU Polyurethane Sandwich Wall Panel

1.What is the most important property of a sandwich panel?

Excellent thermal insulation performance, high strength, light weight, easy to install. Beautiful, decorative strong.

2. How long do sandwich panels last?

In general, the service life of qualified sandwich board can reach 20-30 years. The service life can be extended through normal maintenance and enclosure.

3.What is the disadvantage of a PU sandwich panel?

Fire resistance is limited. If there are fire performance requirements, by adding flame retardants to make it reach a certain fire rating. Or it can be combined with rock wool to achieve better flame retardant effect.

4. What type of insulation is used in sandwich panels?

General thermal insulation core materials are as follows: Expanded Polystyrene (EPS), Extruded Polystyrene (XPS), Polyurethane (PU), Polyisocyanurate (PIR), Rock wool and glass wool.

5. How thick are sandwich panel walls?

50mm,75mm,100mm,120mm are widely used. If you want better strength and heat insulation performance, you can choose a thicker panel such as 150mm,200mm, etc.

Copyright @ 2025 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy