PU/PIR Cold Room Sandwich Panels deliver outstanding thermal insulation and fire resistance for cold storage solutions. Crafted with durable materials, they excel in cold rooms, freezers, and clean rooms. These panels boost energy efficiency, prioritize safety, and guarantee lasting performance in temperature-sensitive settings.

Item No :

PUWall0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

40 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

PU/PIR Cold Room Sandwich Panel |

|

Density |

40~45kg/m³ |

|

Thickness |

40/50/60/75/80/100/120/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

1000mm for wall and roof |

|

Skin material |

PPGL,PPGI,Stainless steel,aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

B1 |

|

Thermal Conductivity |

≤0.023/≤0.02 |

|

Temperature Range |

40~43/40~50℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

Elevate your cold storage solutions with PU/PIR Cold Room Sandwich Panels, designed to deliver top-tier thermal insulation and durability. Boasting a thermal conductivity of 0.019-0.022 W/m·K—the lowest among practical insulation materials—these panels ensure maximum energy efficiency. Crafted with high-pressure continuous foaming technology, they feature a uniform foam structure with a cell density of 200,000 per cm³ and a 97% closed-cell rate, minimizing water vapor penetration for long-lasting performance. This makes them a standout choice for maintaining consistent temperatures in cold chain facilities.

Beyond insulation, these panels excel in fire resistance, utilizing polyurethane foam that forms a protective coking layer when exposed to flames, avoiding the melting or dripping seen in EPS or XPS. Paired with metal facings, they achieve a B1 fire rating (national standard 8624-2012), enhancing safety. The innovative pentane technology uses eco-friendly, non-fluorinated materials, aligning with global ozone protection standards while reducing environmental impact. Additionally, the proprietary airtight technology eliminates cold steam bridges, ensuring seamless integration and superior airtightness—perfect for air-conditioned warehouses.

For sustainability and cost savings, these panels reduce energy consumption by up to 30%, thanks to their advanced insulation system. Hygienic and resistant to bacteria, they meet the strict demands of the cold chain industry. Prefabricated for easy, rapid installation, they shorten construction timelines and cut labor costs, offering a reliable, green solution for modern cold storage needs.

3 The Technical Specifications of Cold Storage Sandwich Panel

|

Thickness /mm |

Temperature difference between inside and outside/℃ |

Height of wall panel/m |

Length of roof panel/m |

Applicable cold storage temperature/℃ |

|

100 |

30 |

5 |

4.45 |

-15 |

|

125 |

35 |

5.5 |

5.2 |

-20 |

|

150 |

50 |

6 |

5.85 |

-25 |

|

175 |

65 |

6.5 |

6.3 |

-30 |

|

200 |

75 |

7 |

6.8 |

-40 |

Selecting cold storage sandwich panels, thickness is the key to mastering temperature control. Our panels are crafted to match specific temperature differences between interior and exterior environments, ensuring your cold storage operates efficiently. A 100mm thick panel supports a 30°C differential, ideal for -15°C conditions, with wall heights up to 5 meters and roof spans of 4.45 meters. For harsher demands, a 125mm panel handles 35°C differences, maintaining -20°C, while a 150mm option tackles 50°C gaps for -25°C storage. Pushing further, 175mm panels manage 65°C variances for -30°C, and the robust 200mm thickness excels at 75°C differences, perfect for -40°C extremes.

Built to endure internal-external pressure shifts and contraction stresses, these panels thrive under a heat flow of 8-10 W/m². However, exceeding listed heights or lengths, or facing wind loads, requires additional supporters to maintain stability. Our cold storage sandwich panels blend durability with energy efficiency, offering tailored insulation solutions. Optimize your facility’s performance by choosing the right thickness for your temperature needs—whether it’s chilled goods or deep-freeze applications, we’ve got you covered with reliable, high-performance panels.

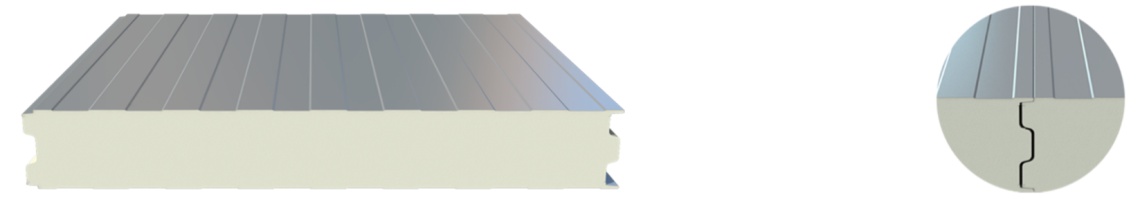

4 Plate Type and Node Figure

Cold storage board plug-in interface-C type

Cold storage board plug-in interface-E type

5 Application Areas of Cold Storage Panels

Cold Storage Panels are indispensable solutions for maintaining temperature-controlled environments across a variety of industries, ensuring the safety and quality of perishable items. In the food sector, these panels excel in rapid freezing and refrigeration processes, locking in the freshness and nutritional value of goods from production to consumption. They are equally critical in food processing facilities, providing consistent temperature regulation to meet stringent quality and safety standards. For dairy storage, Cold Storage Panels keep milk, cheese, and other perishables at ideal conditions, preventing spoilage and prolonging shelf life. In the pharmaceutical industry, they play a vital role in preserving the potency of biological products and medicines, ensuring their effectiveness for critical healthcare needs. These panels are also a cornerstone of indoor cold storage setups, such as warehouses and distribution hubs, offering dependable large-scale cooling capabilities. Beyond static storage, they are essential in cold-chain transportation vehicles, upholding the integrity of the cold chain to deliver goods in perfect condition. Featuring cutting-edge insulation technology, Cold Storage Panels deliver exceptional thermal efficiency, reducing energy costs and supporting sustainable operations. Their robust design guarantees durability and performance, even under challenging conditions. By minimizing energy use, they align with eco-friendly practices, making them a smart choice for modern businesses. From safeguarding food quality to securing pharmaceutical supplies and optimizing logistics, Cold Storage Panels stand out as a reliable, versatile asset for professionals globally.

6 FAQS of PU/PIR Cold Room Sandwich Panels

1. What are cold room panels called?

Answer: Cold room panels, like Propanel’s, are insulated boards built for temperature-controlled spaces. They deliver top-notch thermal insulation and durability, perfect for cold storage, food safety, and pharmaceutical needs with energy-saving design.

---

2. What is a sandwich wall panel called?

Answer: Sandwich wall panels, such as Propanel's, are layered panels with an insulating core between sturdy sheets. They offer excellent fire resistance, insulation, and strength for industrial buildings, homes, and commercial projects.

---

3. What materials are used in cold room panels?

Answer: Propanel’s cold room panels use high-density PU or PIR foam cores wrapped in tough metal skins. These ensure superior thermal insulation, moisture resistance, and fire safety for reliable cold storage solutions.

---

4. What is the specification of cold room panel?

Answer: Propanel’s cold room panels range from 40mm to 300mm thick, with a low 0.02 W/m·K conductivity. Their airtight, closed-cell foam design boosts energy efficiency and maintains stable temperatures effortlessly.

---

5. What equipment is used in the cold room?

Answer: Cold rooms rely on refrigeration units, evaporators, and condensers. Propanel’s panels enhance these systems with seamless fit, optimizing energy use and ensuring consistent cooling for perishables and sensitive items.

---

Copyright @ 2025 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy