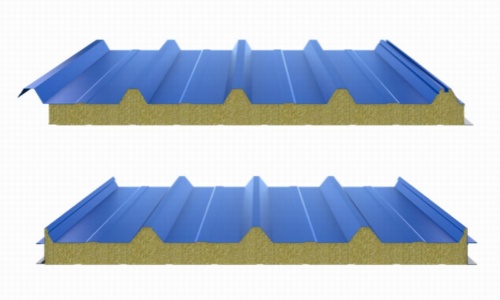

Rock Wool Sandwich Roof Panels deliver exceptional fire resistance, thermal insulation, and durability. Featuring a rock wool core for energy efficiency and metal sheets for robust weather protection, they’re perfect for industrial, commercial, or residential roofing. Lightweight and eco-friendly, these panels ensure quick installation, offering a cost-effective, long-lasting solution with superior soundproofing and sustainability.

Item No :

ROCKROOF0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

120 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

|

|

cDensity |

Rock wool: 50~200 kg/m³, PU Sealing: 40 kg/m³ |

|

Thickness |

50/75/100/120/150mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

1000mm for wall and 950/1000mm for roof |

|

Skin material |

PPGL, PPGI, Stainless, Steel, Aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

A |

|

Thermal Conductivity |

0.04~0.055 |

|

Temperature Range |

800℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

With a Class A non-combustible rock wool core, sourced from natural volcanic rock, this panel delivers over 2 hours of fire resistance, offering unmatched protection for buildings like warehouses, schools, or offices. It’s a top pick for those prioritizing fire-resistant roofing.

Designed for durability, its density spans 80kg/m³ to 150kg/m³—typically 120kg/m³—with a compressive strength of ≥150KPa. Sandwiched between two robust steel layers, it stands firm against storms, winds, and wear, ensuring lasting performance in any climate.

For thermal insulation, the panel shines. Its fine rock wool fibers achieve a thermal conductivity of ≤0.043W/(m·K), while optional PU edges drop to ≤0.025W/(m·K). This creates a cozy indoor environment—warm in winter, cool in summer—cutting energy bills and boosting comfort. It’s a standout among thermal insulation panels.

Sustainability sets it apart. Made from recyclable, inorganic materials via an eco-friendly process, it reduces your carbon footprint. Plus, its prefabricated structure speeds up installation, covering 600㎡ to 800㎡ daily, saving time and labor costs.

Whether you’re an architect, contractor, or property owner seeking eco-friendly building materials, the Rock Wool Sandwich Roof Panel offers reliability and innovation. Optimize your project with a roofing system that excels in safety, insulation, and green design—perfect for modern, responsible construction.

Allowable vertical load and heat transfer coefficient of PROPANEL new model fireproof rock wool sandwich roof panel with pu sealing (allowable deflection f ≤ L/240)

|

Thickness (mm) |

Heat transfer (W/m2k) |

Weight (kg) |

Load P=KN/m2 |

0.60 |

0.80 |

1.00 |

1.20 |

1.50 |

|

50 |

0.75 |

15.74 |

L(m) |

3.78 |

3.31 |

2.98 |

2.71 |

2.41 |

|

75 |

0.53 |

18.68 |

L(m) |

4.83 |

4.21 |

3.76 |

3.42 |

3.01 |

|

100 |

0.41 |

21.62 |

L(m) |

5.77 |

5.02 |

4.47 |

4.04 |

3.55 |

|

150 |

0.31 |

27.51 |

L(m) |

7.53 |

6.54 |

5.82 |

5.26 |

4.61 |

Note:0.5mm outer steel sheet and 0.4mm inner steel sheet.

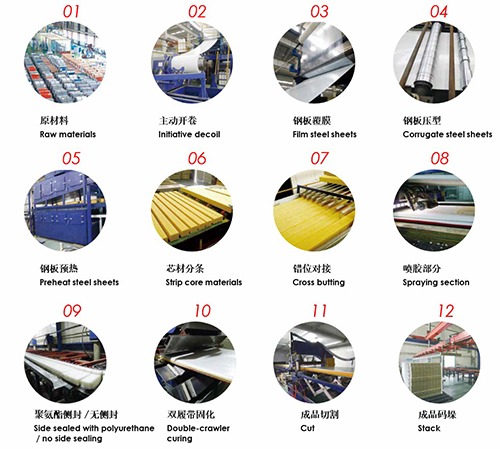

The process begins with automated decoiling, followed by optional film application for enhanced protection. Steel sheets can be profiled into corrugated forms to increase strength and rigidity. Preheating ensures optimal adhesion with the core material. We meticulously process and cross-butt strips of high-density rock wool, creating a seamless and highly effective insulation layer. A specialized spraying section applies high-performance adhesives, bonding the layers together before entering the double-crawler curing oven. This critical stage guarantees uniform pressure and perfect lamination. Depending on project specifications, panels can be produced with or without polyurethane side sealing for improved weather resistance and edge protection. The continuous production line culminates in precise cutting to specified lengths, automated stacking for efficient handling, and secure packaging for safe transportation.

Our Rock Wool Sandwich Roof Panels are the ideal choice for industrial, commercial, and residential buildings demanding exceptional insulation, fire safety, and longevity.

4 Project cases of Rock wool Sandwich Roof Panel

Project cases of Rock wool Sandwich Roof Panel--Australian Animal Husbandry Base 20000㎡ in 2018

5 Honors and Certifications of Propanel

Our panels have undergone rigorous testing and successfully achieved FM, CE, and UL certifications, providing you with unparalleled assurance. The FM certification validates Propanel's superior wind resistance, robust fire resistance capabilities, and outstanding impact resistance, ensuring long-term durability and safety. The CE mark confirms our commitment to meeting stringent EU standards for safety, health, and environmental protection, making Propanel a responsible choice for sustainable construction. Furthermore, the UL certification underscores the exceptional fire resistance and overall safety performance of our rock wool sandwich panels. These authoritative certifications demonstrate Propanel's unwavering dedication to delivering top-tier building materials that meet and exceed global standards. Choose Propanel Rock Wool Sandwich Panels for reliable protection, superior insulation, and the peace of mind that comes with internationally recognized quality assurance. Keywords: Rock Wool Sandwich Panels, FM Certified, CE Certified, UL Certified, Fire Resistant Panels, Wind Resistant Panels, Impact Resistant Panels, Safety Standards, Building Materials, Construction Panels, High-Quality Insulation.

6 FAQs for Propanel Rock wool Sandwich Roof Panel

1. What are the disadvantages of a sandwich panel roof?

Sandwich panel roofs may face corrosion, require maintenance, and have limited design flexibility. Propanel ensures durability and weather resistance.

2. Is rockwool good for roof insulation?

Yes, rockwool offers excellent thermal and fire resistance for roofs. Propanel’s rockwool panels enhance energy efficiency.

3. What are the risks of sandwich panels?

Risks include moisture damage, fire spread if not certified, and structural wear. Propanel panels are fire-resistant and durable.

4. Are sandwich panels load bearing?

Yes, sandwich panels can be load-bearing with proper design. Propanel ensures strength for structural support.

5. Is sandwich panel waterproof?

Sandwich panels can be waterproof with sealed edges. Propanel uses PU sealing for moisture resistance.

Copyright @ 2025 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy