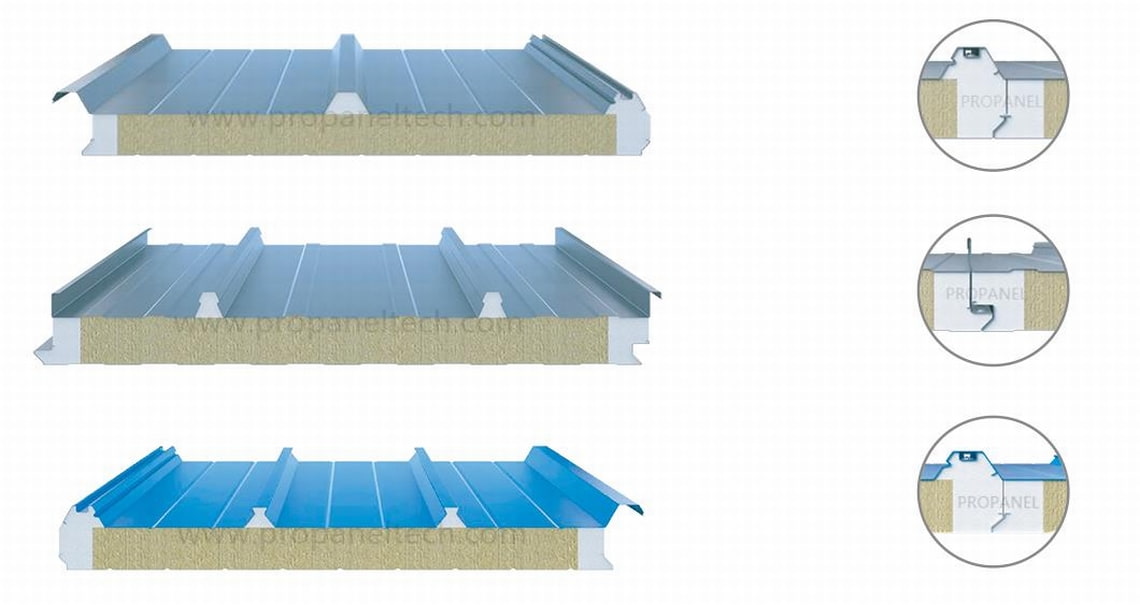

Combines the advantages of rockwool and polyurethane. At the same time, it has the non-flammability of rock wool material and the high-quality thermal insulation performance of polyurethane material. The unique polyurethane edge enhances the tightness of the plate, waterproof, moisture-proof, sand-proof and durable.

Item No :

ROCKPUR0002Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

PU:40 Kg/m³; Rock wool: 120 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

Rock wool Sandwich Roof Panel with PU Sealing |

|

Density |

Rock wool: 50~200 kg/m³, PU Sealing: 40 kg/m³ |

|

Thickness |

50/75/100/120/150mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

1000mm for wall and 950/1000mm for roof |

|

Skin material |

PPGL, PPGI, Stainless, Steel, Aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

A |

|

Thermal Conductivity |

0.04~0.055 |

|

Temperature Range |

800℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

High quality thermal insulation: polyurethane thermal conductivity between 0.020-0.025W /(m · K), effectively prevent heat transfer, keep indoor temperature stable, reduce building energy consumption.

Class A fire performance: Rock wool is A non-combustible material with class A fire performance.

Good sealing performance: polyurethane edge sealing effectively prevents the intrusion of rain, wind and sand, improves the tightness and water resistance of the roof panel, and avoids roof leakage.

High structural strength: The roof panels are made of high strength rockwool core material and polyurethane edge sealing, which has good bearing capacity and can adapt to different roof structures and load requirements.

Corrosion resistance and aging resistance: The selection of high-quality galvanized color coated sheet as the substrate, corrosion resistance is strong, not easy to aging, the service life of up to 30-50 years.

Convenient construction: the plate specifications are unified, light weight, easy to handle and install, effectively shorten the construction period, improve construction efficiency, save costs.

Excellent environmental performance: rock wool is a kind of green environmental protection material, non-toxic and tasteless, harmless to human body and the environment; Polyurethane edge sealing also meets environmental requirements during production and use.

Beautiful and practical: polyurethane edge can make the edge of the roof panel neat, smooth, beautiful appearance, but also have practical functions, improve the overall quality of the building.

Allowable vertical load and heat transfer coefficient of PROPANEL new model fireproof rock wool sandwich roof panel with pu sealing (allowable deflection f ≤ L/240)

|

Thickness (mm) |

Heat transfer (W/m2k) |

Weight (kg) |

Load P=KN/m2 |

0.60 |

0.80 |

1.00 |

1.20 |

1.50 |

|

50 |

0.75 |

15.74 |

L(m) |

3.78 |

3.31 |

2.98 |

2.71 |

2.41 |

|

75 |

0.53 |

18.68 |

L(m) |

4.83 |

4.21 |

3.76 |

3.42 |

3.01 |

|

100 |

0.41 |

21.62 |

L(m) |

5.77 |

5.02 |

4.47 |

4.04 |

3.55 |

|

150 |

0.31 |

27.51 |

L(m) |

7.53 |

6.54 |

5.82 |

5.26 |

4.61 |

Note:0.5mm outer steel sheet and 0.4mm inner steel sheet.

Compared with common core materials such as polystyrene, polyurethane, glass wool, etc., rock wool has the following advantages

Superior fire resistance

Rock wool belongs to class A non-combustible material, it will not burn under high temperature open flame, nor will it produce toxic smoke and gas, which can effectively prevent the spread of fire and buy time for personnel evacuation and fire rescue.

Good thermal insulation effect

The thermal conductivity of rock wool is low, generally between 0.03-0.045W /(m · K), which is comparable to glass wool, better than polystyrene, and slightly worse than polyurethane. However, the thermal insulation performance of rock wool is more stable in high temperature environment, and it is not easy to greatly change the thermal conductivity due to temperature changes. For example, in the thermal insulation applications of some industrial high temperature workshops, rock wool can maintain a good thermal insulation effect for a long time.

Excellent sound absorption and noise reduction performance

There are a large number of pores and fibers in the rock wool, which has a good absorption effect on sound wave, and has a remarkable effect on sound absorption and noise reduction. In contrast, polystyrene and polyurethane sound absorption performance is poor, although glass wool also has a certain sound absorption ability, but rock wool in the low frequency band sound absorption effect is better, can effectively reduce environmental noise, improve indoor acoustic environmental quality.

Strong chemical stability

Rock wool has good corrosion resistance and is not easy to be eroded by acids, alkalis and other chemicals, and can still maintain stable performance under harsh environmental conditions. Polystyrene and polyurethane in some chemical environments may occur aging, embrittlement and other phenomena, affect the service life.

Green and environmental protection

Rock wool is a natural, non-toxic, harmless material, does not contain harmful substances, no harm to the human body and the environment. Its production process energy consumption is relatively low, and can be recycled, in line with environmental requirements.

4 Project cases of Rock wool Sandwich Roofing Panel with PU Sealing

Project cases of Rock wool Sandwich Roofing Panel with PU Sealing--Canadian Logistics Warehouse 2000 square meters 2017

5 RFQS of Rock Wool Sandwich Roofing Panels with PU Sealing

1. What is a rock wool sandwich panel?

--The rock wool sandwich board is composed by two steel plates and rock wool insulated core material. It not only has the strength and toughness of steel plate, but also takes into account the thermal insulation and fire protection performance of rock wool, providing an integrated solution for enclosure.

2. Why choose ROCKWOOL solutions?

--The rock wool fire rating is Class A, which is the best choice for buildings with fire protection requirements.

3. What is the difference between Rockwool and Puf panels?

--Rock wool has non-combustible characteristics, suitable for buildings with high fire rating requirements. PUF has low thermal conductivity and good thermal insulation performance, which is more suitable for buildings with high thermal insulation requirements, such as cold chain and cold storage.

4. Is sandwich panel waterproof?

--The rock wool + polyurethane edge sealing sandwich panel has both the fire rating of rock wool (Class A) and the waterproof performance of polyurethane.

5. How long does ROCKWOOL insulation last?

Rock wool Sandwich panel has a service life of more than 50 years.

Copyright @ 2025 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy