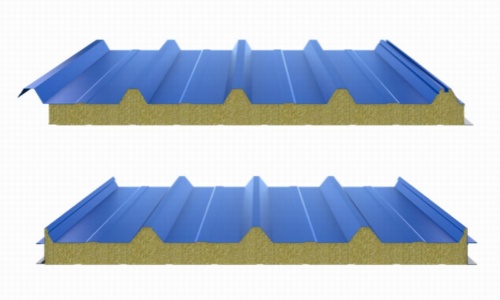

The rock wool core material and steel plate are formed by roller forming and high pressure composite bonding to form a stable, lightweight and energy-saving new building material. With fire, moisture, heat insulation, heat preservation and other building performance, and a variety of choices, beautiful atmosphere.

Item No :

ROCKROOF0002Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

120 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

Rock wool Sandwich Roofing Panel |

|

Density |

Rock wool: 50~200 kg/m³, PU Sealing: 40 kg/m³ |

|

Thickness |

50/75/100/120/150mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

1000mm for wall and 950/1000mm for roof |

|

Skin material |

PPGL, PPGI, Stainless, Steel, Aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

A |

|

Thermal Conductivity |

0.04~0.055 |

|

Temperature Range |

800℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

Fire protection: As A class A non-combustible material, the rock wool core made of natural rock has a fire resistance limit of more than 4 hours, adding a layer of solid fire protection shield to the building. High density and high strength: Density between 80kg/m³ -150kg /m³, commonly used 120kg/m³, compressive strength ≥150KPa, and two layers of steel closely combined, cope with extreme weather calmly.

Excellent thermal insulation effect: Slender and flexible rock wool fiber, pure rock wool core material thermal conductivity ≤0.043W/ (m · K), high-quality PU edge can be ≤0.025W/ (m · K), keep indoor warm in winter and cool in summer.

Green environmental protection: Inorganic materials are pollution-free, green production process, recyclable

Easy installation: Prefabricated components, an average of 600㎡ -800 ㎡ per day, the construction period is greatly shortened.

Allowable vertical load and heat transfer coefficient of PROPANEL new model fireproof rock wool sandwich roof panel with pu sealing (allowable deflection f ≤ L/240)

|

Thickness (mm) |

Heat transfer (W/m2k) |

Weight (kg) |

Load P=KN/m2 |

0.60 |

0.80 |

1.00 |

1.20 |

1.50 |

|

50 |

0.75 |

15.74 |

L(m) |

3.78 |

3.31 |

2.98 |

2.71 |

2.41 |

|

75 |

0.53 |

18.68 |

L(m) |

4.83 |

4.21 |

3.76 |

3.42 |

3.01 |

|

100 |

0.41 |

21.62 |

L(m) |

5.77 |

5.02 |

4.47 |

4.04 |

3.55 |

|

150 |

0.31 |

27.51 |

L(m) |

7.53 |

6.54 |

5.82 |

5.26 |

4.61 |

Note:0.5mm outer steel sheet and 0.4mm inner steel sheet.

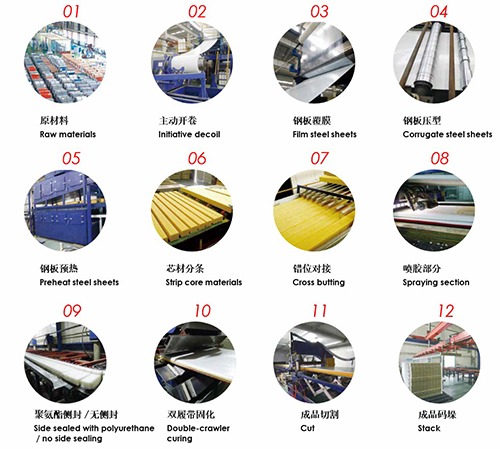

01 Stainless steel coil and color coated galvanized coil are used as the upper and lower substrate of the composite plate

02 Initiative decoil

03 Film steel sheets

04 Corrugated steel sheets

05 Preheat steel sheets

06 Strip core materials (rock wool)

07 Rock wool Cross butting

08 Spraying section

09 No side sealing/Side sealed with polyurethane

10 Double-crawler curing

11 Cut into pieces

12 Stack

13 Package automatically

Ours' rock wool combines fire-resistant insulation, energy efficiency, and environmental sustainability into one robust package. Whether you’re insulating a home or a commercial space, its advanced properties make it a smart, long-term investment. Opt for Rock Wool to elevate safety, comfort, and eco-consciousness in your next project.

4 Project cases of Rock wool Sandwich Roof Panel

Project cases of Rock wool Sandwich Roof Panel--Australian Animal Husbandry Base 20000㎡ in 2018

5 Honors and Certifications of Propanel

Propanel Rock wool Sandwich Panels have successfully passed international certifications such as FM, CE, and UL through authoritative testing. FM certification shows its excellent wind resistance, fire resistance, and impact resistance; CE certification ensures that the product complies with EU safety, health, and environmental protection standards; UL certification proves its excellent fire resistance and safety performance. Stringent certifications create a model of quality.

Copyright @ 2025 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy