Cold storage sandwich panels offer superior insulation and airtightness, boosting energy efficiency and maintaining consistent temperatures. Crafted from robust PU or PIR foam cores with metal cladding, they resist moisture, fire, and rust. Perfect for food, pharma, and industrial use, these panels ensure fast setup, minimal upkeep, and enduring reliability.

Item No :

PUWall0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

40 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

Sandwich Panels for Cold Storage Room |

|

Density |

40~45kg/m³ |

|

Thickness |

40/50/60/75/80/100/120/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

1000mm for wall and roof |

|

Skin material |

PPGL,PPGI,Stainless steel,aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

B1 |

|

Thermal Conductivity |

≤0.023/≤0.02 |

|

Temperature Range |

40~43/40~50℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

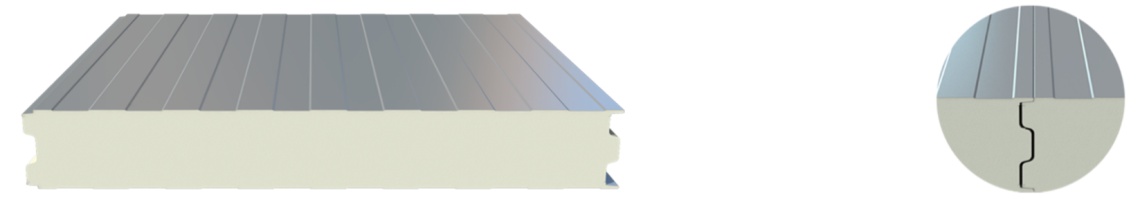

These panels consist of two sturdy metal sheets encasing a thick insulating layer, often made from high-quality materials like polyurethane foam. This unique design delivers outstanding thermal insulation, making them perfect for keeping cold storage spaces consistently chilled. Unlike traditional building methods, sandwich panels are lightweight yet strong, allowing for quick assembly without sacrificing durability.

What sets these panels apart is their streamlined installation process. Delivered in pre-cut sections, they fit together effortlessly with tight, interlocking joints. This creates a solid barrier against air leaks and moisture, critical for preserving perishable items like food or pharmaceuticals. For anyone constructing a cold storage facility—say, a warehouse for fresh produce—these panels reduce setup time and labor costs significantly. Their energy-saving properties also stand out, as the insulation minimizes heat transfer, cutting down on refrigeration expenses month after month.

Durability is another key benefit. Built to endure harsh conditions, sandwich panels resist wear and tear, ensuring your cold storage room stays functional for years. They’re also versatile, suitable for new builds or retrofitting older structures. With a clean, professional finish, they enhance the facility’s appearance while meeting strict hygiene standards. In short, installing sandwich panels brings together speed, efficiency, and long-term value, making them a top choice for cold storage projects aiming for performance and cost savings.

3 The Technical Specifications of Cold Storage Sandwich Panel

|

Thickness /mm |

Temperature difference between inside and outside/℃ |

Height of wall panel/m |

Length of roof panel/m |

Applicable cold storage temperature/℃ |

|

100 |

30 |

5 |

4.45 |

-15 |

|

125 |

35 |

5.5 |

5.2 |

-20 |

|

150 |

50 |

6 |

5.85 |

-25 |

|

175 |

65 |

6.5 |

6.3 |

-30 |

|

200 |

75 |

7 |

6.8 |

-40 |

Our panels, available in thicknesses from 100mm to 250mm, are tailored to meet the specific requirements of different products:

Vegetables & Fruits (50–100mm): Maintain crisp freshness with balanced humidity control and moderate insulation.

Fish & Meat (100–200mm): Ensure long-term preservation with enhanced thermal retention and anti-bacterial surfaces.

Blast Freezers (200–250mm): Deliver ultra-low-temperature stability (-40°C) for rapid freezing and minimal energy loss.

Core Features:

PU/PIR Insulation: High-density foam cores with thermal conductivity as low as 0.022 W/m·K.

Airtight Seals: Interlocking joints and EPDM gaskets eliminate thermal bridging and moisture ingress.

Hygienic Surfaces: Food-grade stainless steel or coated aluminum-zinc panels for easy cleaning and compliance with FDA/CE standards.

Durability: Corrosion-resistant coatings withstand harsh environments, including coastal and chemical exposure.

Applications:

Produce cold storage (5–10°C)

Seafood freezing (-25°C)

Meat processing plants

Pharmaceutical cold chain logistics

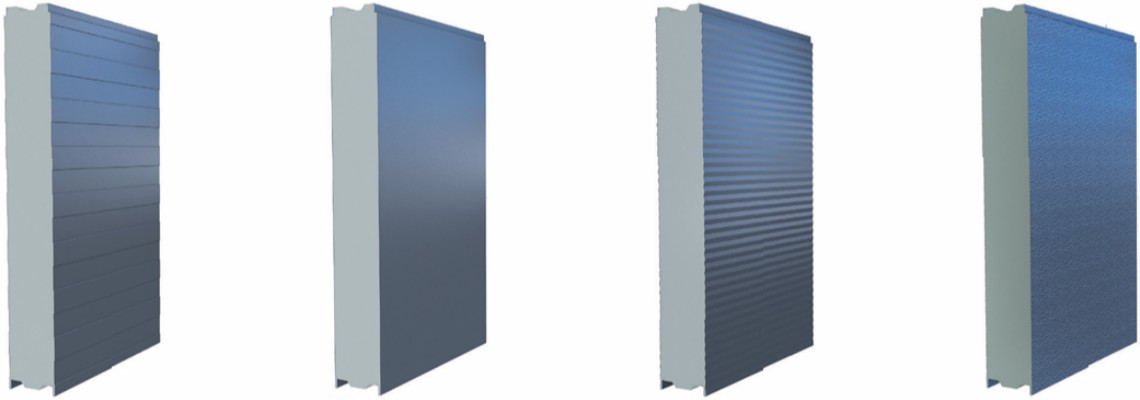

4 Plate Type and Node Figure

Cold storage board plug-in interface-C type

Cold storage board plug-in interface-E type

5 Application Areas of Cold Storage Panels

Cold storage panels are engineered to meet the rigorous demands of industries requiring controlled temperature environments. From food processing to pharmaceuticals, these panels ensure optimal preservation, safety, and efficiency across critical sectors:

1. Food Processing & Rapid Freezing

Ideal for blast freezing (-40°C to -18°C), our panels maintain consistent ultra-low temperatures to lock in freshness for seafood, meats, and ready-to-eat meals. Anti-bacterial surfaces and airtight joints comply with HACCP and ISO 22000 standards.

2. Dairy & Perishable Storage

Designed for dairy products (2°C to 6°C), the panels prevent bacterial growth with hygienic, easy-to-clean finishes while minimizing energy consumption.

3. Pharmaceutical & Biotech Facilities

Temperature-stable panels (2°C to 8°C) ensure integrity of vaccines, medicines, and biologics. Fire-rated cores (EN 13501-1) and moisture-proof seals meet GMP and WHO guidelines.

4. Cold Chain Logistics

Lightweight yet durable panels are tailored for refrigerated trucks and containers, offering shock resistance and thermal efficiency (-25°C) to protect goods during transit.

5. Commercial Indoor Cold Rooms

Customizable sizes and finishes suit supermarkets, restaurants, and warehouses, balancing cost-effectiveness with robust insulation (R-value up to 6.5 per inch).

Copyright @ 2025 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy